Devulcanization of vulcanized rubber products

The present invention suggests a novel device and method for the plasma-based devulcanization of vulcanized rubber, which can be reused as raw material for the fabrication of vulcanizable rubber particles.

Challenge

With regard to the rising material and energy costs, eco-friendly and sustainable technologies are increasingly gaining attention. Recycling is one possibility to face these issues and provide extensive solutions. In general, recycling represents the process of collection and processing of materials, which would otherwise be thrown away as trash, and turning them into new products. Recycling of rubber can be achieved by mechanical, thermal, irradiation (e.g. plasma and microwave) and/or chemical methods. Although these methods provide certain advantages, mostly they can be energy-intensive and/or require additional resources (e.g. high temperature and chemicals). Within the scope of the aforementioned aspects and in relation to the conventional fabrication of rubber materials and/or rubber-based products, recycled rubber material is more preferred and desired. However, in order to use recycled rubber for further processing, it needs to fulfill certain requirements (e.g. possibility for vulcanization) and quality standards.

Our Solution

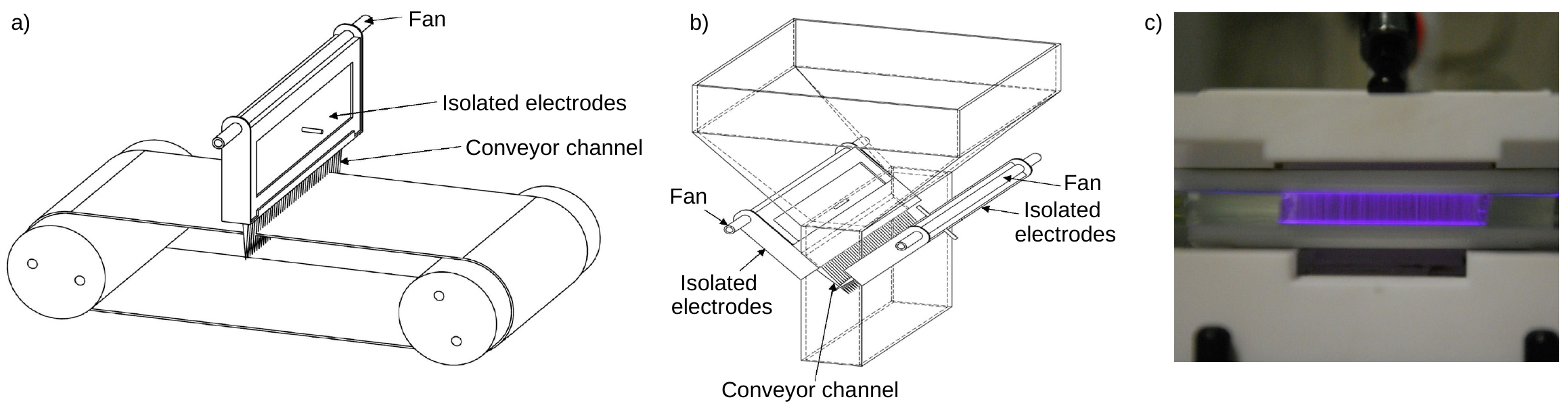

The present invention provides an alternative approach for the chemical-free and low-energy devulcanization of (in particular) sulfur-vulcanized rubber. The process is characterized by grinding the (initial) vulcanized rubber into particles with a size of 2 mm, more preferentially down to sizes of 1 mm and 0.5 mm. In the next step, a plasma is generated by dielectrical barrier discharge (DBD) and used to fabricate rubber particles, which are devulcanized on the surface. The process gas used for the plasma can be oxygen, which can optionally be mixed with nitrogen and CO2. The initial rubber material (used for the devulcanization process) can be vulcanized with sulfur and optionally contain silicates, metals (e.g. in the form of metal oxides) and soot. Moreover, the rubber can contain oxygen, which might arise from aging within the sulfur bridges. Exemplarily, vulcanizable rubber particles with size of 1 mm can be fabricated from old car tires. Such rubber particles can be further processed by e.g. dispersing or extrusion into a vulcanizable rubber mixture, which contains sulfur as vulcanization agent. A mixture of a vulcanizable rubber mixture and devulcanized particles can be pressed in a form and vulcanized. Thereby, the devulcanized rubber particles are bonded with the rubber mixture via surface vulcanization. The conveyor channel can be designed as a band-conveyor (Fig. 1a) or in a drop-distance configuration (Fig. 1b). In general, the conveyor channel can be outside the region between the electrodes, while the device can exhibit a fan, which is pushing the DBD-plasma towards the rubber particles.

Fig. 1: Possible device designs a) and b) for the devulcanization of vulcanized rubber. Both versions are capable for a continuous operation. In c) the device for the devulcanization of vulcanized rubber is shown in operation. The ignited plasma is highlighted in purple color (adaptation after patent application).

Fig. 1: Possible device designs a) and b) for the devulcanization of vulcanized rubber. Both versions are capable for a continuous operation. In c) the device for the devulcanization of vulcanized rubber is shown in operation. The ignited plasma is highlighted in purple color (adaptation after patent application).

Advantages

- No tempering required (operation at room temperature possible)

- No chemicals required

- Minor/low energy input

- Continuous process control/management

- Fast/rapid processing

- Various device layouts available

- Easy feasibility (flexible process adaptation)

Applications

- Devulcanization of rubber products (e.g. rubber sleeves, car and bike tires)

- Fabrication of vulcanizable rubber particles

Development Status

The device functionality and devulcanization process have been successfully approved.

Patent Status

German patent application: DE102017221102B4

Patent holder: Clausthal University of Technology

Contact

Dr. Mirza Mackovic

Patent Manager Technology

E-Mail: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Tel.: +49 551 30724 153

Reference: CPA-2264-T238