Freeform shaping of fused silica substrates

A method has been found for freeform shaping of optical surfaces via a stress-induced viscous deformation of glass plates. Fused silica substrates can be deformed by covering them with substoichiometric silicon oxide followed by a laser patterning process and an annealing step.

Challenge

Freeform optics enable improved optical solutions to current demands in laser optics but fabrications usually requires complicated precision machining processes to manufacture them. Usually they are produced by forming and finishing processes like turning, milling, grinding, water jet polishing, magnetorheological finishing, ion beam figuring or reactive atom plasma processing. Also direct laser ablation and laser polishing can be applied or forming processes like compression molding and slumping can be used. All mentioned methods demand specific precision machining or high effort while providing low flexibility. Molding is only viable when fabricating high quantities.

Our solution

The method presented here provides an alternate process to create freeform optics in which monolithic fused silica phase masks are produced by deposition of a substoichiometric silicon oxide (silicon suboxide) film on a fused silica substrate, excimer laser structuring of the film by rear side ablation and oxidation of the structured film to silicon dioxide. In rear side ablation, the laser light is transmitted by the substrate and absorbed in the film close to the film substrate interface, resulting in a binary ablation process. During oxidation of the silicon suboxide film, taking place at high temperatures (1100 °C), the film thickness increases and a compressive film stress is induced. This procedure enables the possibility of stress-induced freeform shaping of fused silica substrates via a viscoelastic deformation. This approach could be used for production of custom-made freeform mirror substrates or correction plates.

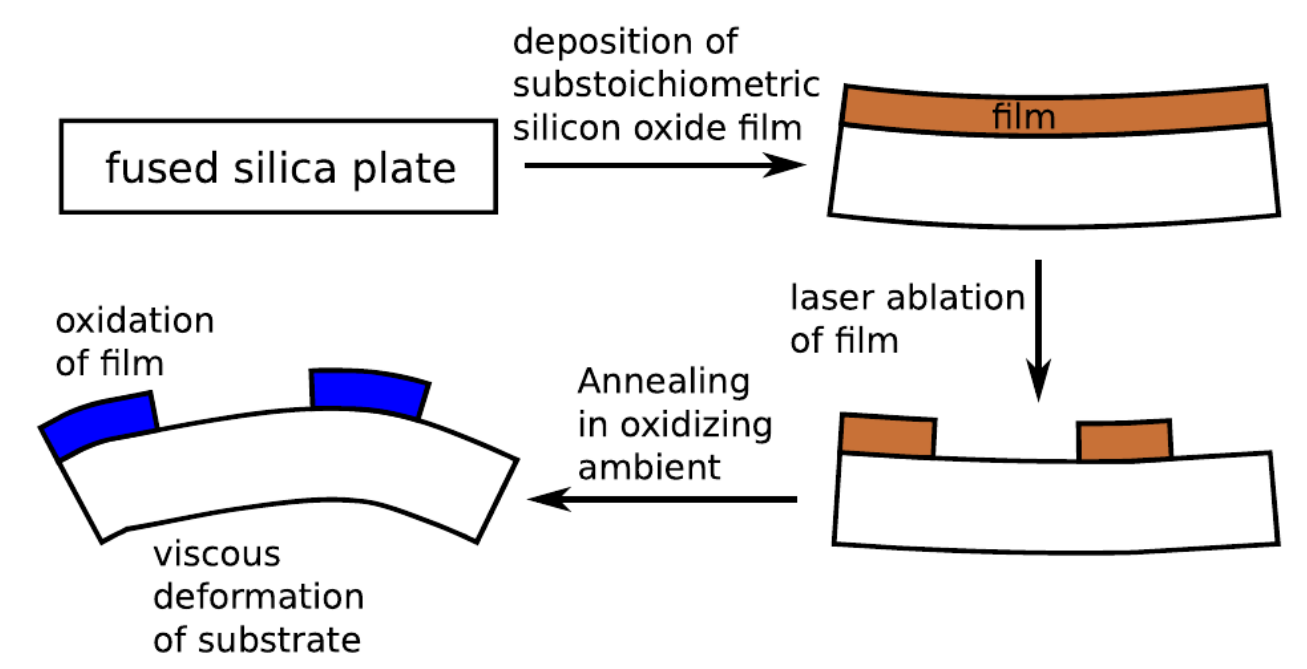

Schematic illustration of the process for stress-induced freeform shaping of fused silica plates. The silicon suboxide film deposited on one side of the plate is patterned by ablation with an ArF excimer laser. Annealing leads to an oxidation of the film, which causes a compressive stress, and a decrease of substrate viscosity, allowing for a signification nonrecoverable deformation. (source: Dr. Jürgen Ihlemann, Institut für Nanophotonik Göttingen e.V.)

Schematic illustration of the process for stress-induced freeform shaping of fused silica plates. The silicon suboxide film deposited on one side of the plate is patterned by ablation with an ArF excimer laser. Annealing leads to an oxidation of the film, which causes a compressive stress, and a decrease of substrate viscosity, allowing for a signification nonrecoverable deformation. (source: Dr. Jürgen Ihlemann, Institut für Nanophotonik Göttingen e.V.)

Advantages

- Highly flexible, high precision freeform optics shaping

- Only flat polished surface and no mold required

- Larger deformations possible compared to an elastic deformation approach

- Complex surface topographies obtainable by appropriate film patterns

Applications

- Flexible, precise freeform shaping of single piece optics (no production high volume required)

Development Status

Process successfully tested and optimized, current studies to further improve the precision

Patent Status

Institut für Nanophotonik Göttingen e.V.

DE102009016113B4 (granted)

References

C. Beckmann et al. - Opt. Exp. 30.5, 6726-6737 (2022)

Contact

Dr. Maria Kamper

Patent Manager Physics & Technology

E-Mail: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Tel.: +49 551 30724 159

Reference: CPA-1192-LLG