Cheap and effective one-step isolation of cellulose nanocrystals

Cellulose nanocrystals (CNCs) are promising natural polymers with a wide range of applications. The technology we can offer allows for the isolation of cellulose nanocrystals from lignocellulose material in a very simple one-step reaction under mild reaction conditions. Using a 50 liter tank for prodcution, the costs are estimated to be in the range of 10% of the actual market price of CNCs in a comparable quality.

Challenge

Despite its potential, the use of CNCs is limited, since today's manufacturing processes are either expensive or have a low / insufficient yield. CNCs are mostly produced by extraction from cellulose pulp by acid-hydrolysis. In the acidic hydrolysis process the reaction conditions are very harsh and low quality CNCs are yielded. An alternative for extraction of CNCs is the oxidative degradation reaction using the TEMPO oxidant, which is much more expensive. In this case the hydroxyl groups of the amorpheous cellulose are oxidized, which results in the destruction of the amorpheous cellulose, while the CNCs are maintained. A cost effective and simple process for the isolation of CNCs from cellulose could make a valuable raw material accessable for a multitude of industrial applications.

Our Solution

Scientists from the university of Göttingen succeeded to developed a simple and cost effective method forextraction of CNCs from lignocellulose contaning matrials. The reaction yields about 30% CNCs of the intial

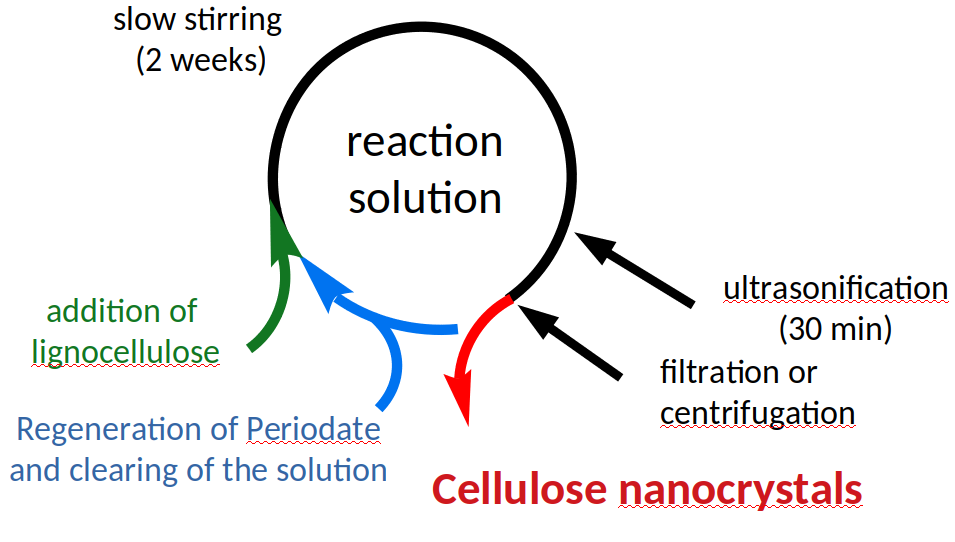

mass when using pulpwood or Flax fibers and about 40% when using microcristalline cellulose. In this process periodate is used for the degradation of the amorpheous nanocellulose. A simple one-step reaction under mild reaction conditions results in a robust isolation method without undesirable side reactions or degradation of the CNCs. It yields very uniform CNCs, which can be extracted from the reaction solution by ultrasonification and filtration or centrifugation.

An additional benefit of this method is the possibility to regenerate the reaction solution and re-use it without a loss in isolation efficiency. The simplicity in combination with the possibility to regenerate the reaction solution dramatically reduces the production costs of CNCs.

Fig. 1 Purification-process of CNCs.

Fig. 1 Purification-process of CNCs.

Advantages

- simple one step reaction

- no side reactions or degradation of crystalline nanocellulose

- high quality and very uniform CNCs

- high yields of up to 40 weight percent from the starting material

- the reaction solution can be recycelt and re-used

- estimated costs for production are only 10% of the actual market price

Development Status

Successfully demonstrated the efficiency of the reaction and recycling on a laboratory scale as well as on a large scale.

Patent Status

US, DE, SI and FI patents are granted.

Patent holder:

Georg-August-Universität Göttingen Stiftung Öffentlichen Rechts

References

Contact

Dr. Vanessa Jensen

Patent Manager Lifesciences

E-Mail: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Tel.: +49 (0) 551 30 724 149

Reference: BioT-2122-SUG

www.sciencebridge.de