Embedded flexible hollow fiber

The technology describes a method to fabricate a virtually ideal wave guide for spectral broadening and high damage threshold. This is achieved by embedding a flexible hollow fiber at ideal straightness in a stretched stat in a thermally conductive solid medium, combining high transmission and high robustness even when high laser powers are coupled in. It is an advancement to the flexible hollow fiber developed at the Institut für Nanophotonik Göttingen e.V. (see reference MM-2010-LLG).

Challenge

Gas-filled hollow fibers have been used for some time to spectrally broaden laser pulses and thus later compress them into shorter pulses. The optical nonlinear effect of self-phase modulation (SPM) is exploited. At IFNANO, this hollow-fiber-based SPM method has already been further developed by plugging and fixing the ends of the hollow fibers, thus improving the transmission and making it possible to use them up to 8 m in length (see reference MM-2010-LLG). One major disadvantage of these stretched thin-walled hollow fibers is the fragility of the fiber which is usually only few hundreds micrometers thick. The front side of the fiber is protected by another invention (reference CPA-2091-LLG) of a preconnection element which allows the coupling of high laser powers into the fiber. Nevertheless, the handling requires a lot of caution because slight since even the slightest vibrations under laser coupling can lead to total failure or tearing of the fiber resulting in extensive repairs. The main weak point of this device is the connection between gluing area and free hanging fiber.

Our solution

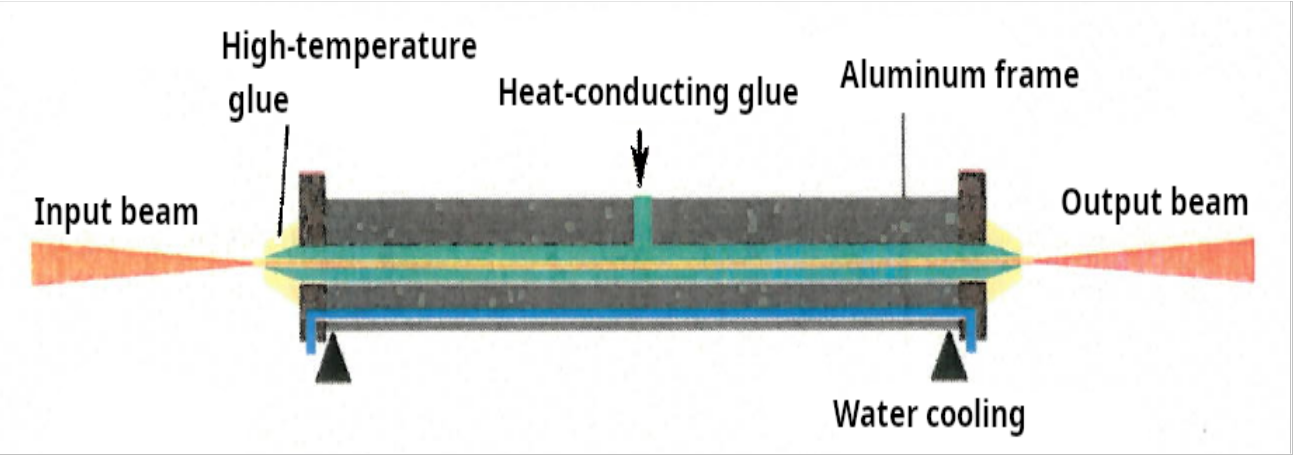

The method described here enables the fabrication of robust, near-ideal waveguides for spectral broadening. The high fracture resistance is based on embedding the hollow fiber in a hardening compound along the entire fiber length. This way, the straight state of the fiber, which is necessary for ideal waveguiding, is ensured permanently and without failure. The aforementioned compound is also thermally conductive (2-component epoxy resin adhesive) and thus enables heat to be dissipated when operating at high average laser powers. The flexible hollow fiber is guided through a frame and which is position in a defined manner on support points. At both ends, nozzles are inserted and these are pulled with a defined tensile force. Then the heat-conducting, curing compound is filled into the middle of the frame profile. After hardening, the nozzles are removed and the tensile force is relieved at both ends and the fiber is cleanly separated. Additionally the invention covers the application of a layered package of high temperature adhesive and thermally conductive adhesive on the in couple side of the fiber for easy repair of damage caused by less than ideal coupling in addition to the possibility to split long hollow fiber device of up to 8 m in half for easier transportation and reassembling at the installation site.

Incoupling of laser light (orange) into an embedded flexible stretched hollow fiber within a heat-conducting compound (green) in an aluminum frame (grey). (source: Dr. Andreas Blumenstein, Institut für Nanophotonik Göttingen e.V.)

Incoupling of laser light (orange) into an embedded flexible stretched hollow fiber within a heat-conducting compound (green) in an aluminum frame (grey). (source: Dr. Andreas Blumenstein, Institut für Nanophotonik Göttingen e.V.)

Advantages

- Robust design for stretched flexible hollow fibers

- Design is resistant against shocks, no tearing of the fiber, no extensive repairs necessary

- In coupling of high laser power possible due to water cooling and heat conducting glue

- Layered package of high temperature adhesive and thermally conductive adhesive on the in couple side of the fiber for easy repair of damage

- Possibility to cut long hollow fiber devices in half for easier transportation and reassembling at the installation site.

Application

- Industrial application of hollow fibers for spectral broadening and pulse compression

Development Status

Embedding of flexible hollow fiber successfully tested and optimized

Patent Status

Institut für Nanophotonik Göttingen e.V.

DE102021103097.8 (filed)

PCT/EP2022/051132 (filed)

References

Contact

Dr. Maria Kamper

Patent Manager Physics & Technology

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 551 30724 159

Reference: MM-2314-LLG

Tags: Laser physics and optics, Physics and Technology & Software