Diffractive marking of glass

This method provides a fast and efficient way for producing diffractive markings - by ablation of small amounts of material - on glass surfaces. The micro relief, which remains, is producing brilliant spectral colors, when illuminated.

Challenge

Laser marking of metals, plastics and ceramics is a well established technology for, as examples, the enrichment, marking or identification of products and components. The high-resolution marking of glass is still a challenge. Glass hardly absorbs any light in the visible range, thus IR or deep-UV lasers have to be used. Technologies using IR-light do not provide spatial resolution in the µm or sub-µm range, because resolution is scaling with the wavelengths. In contrast, excimer lasers combine several advantages for processing of glass surfaces: short wavelengths in the ultraviolet range are strongly absorbed by glass and plane beam profiles allow the parallel processing of larger areas. Established mask projection techniques can be used for micro-structuring. Mask projection however requires advanced optics and typically used amplitude masks lead to high light losses.

Our Solution

The developed process uses plane laser ablation by excimer lasers using low-loss optical components and methods.

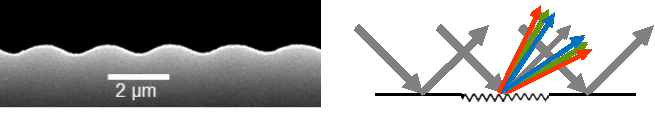

Fig. 1 Periodic surface relief on glass (Image Source Dr. Jürgen Ihlemann, IFNANO Göttingen e. V.)

Fig. 1 Periodic surface relief on glass (Image Source Dr. Jürgen Ihlemann, IFNANO Göttingen e. V.)

A laser interference pattern is generated on the surface. High laser fluence and interference contrast result in periodic laser ablation. The whole beam profile of the laser is being used, resulting in higher throughput and increased efficiency and contrast. The interference pattern is generated by splitting the laser beam into at least two – ore more – beams. The phase mask is imaged by a combining lens on the surface of the material, which is processed. It is possible to move the workpiece continuously, as needed in industrial production or processing. Laser pulses are triggered whenever the workpiece has moved by one or multiple periods of the desired grating. With this method it is now possible to produce micrometer gratings on work piece surfaces - especially glass surfaces – within a very short time frame. The resulting shape then appears intensely colorful, similar to what is known from holographic markings. Different color gratings result from different structure periods of the grating pattern.

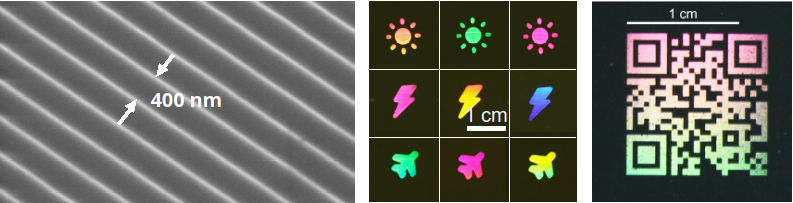

Fig. 2 Left: High resolution grating pattern on fused silica; Middle: Color dependent on illumination and perspective; Right: QR code on a glass surface. (Image Source: Dr. Jürgen Ihlemann, IFNANO Göttingen e. V.)

Fig. 2 Left: High resolution grating pattern on fused silica; Middle: Color dependent on illumination and perspective; Right: QR code on a glass surface. (Image Source: Dr. Jürgen Ihlemann, IFNANO Göttingen e. V.)

For enhancement of flexibility of the applied marking it is possible to use a square or circular aperture combined with the phase mask to pixel images on the work piece. Each of these pixels contains an interference grating. During moving the work piece or the beam it is possible to generate a pixel based marking.

Advantages

- Efficient process with a simple setup, without additives, high process speeds

- Temperature-resistant, long-term stable

- Machine-readable

- Labels with brilliant color shine of high aesthetics, machine-readable

- Structuring without (micro-)cracks

- Possibility to label plane and curved surfaces

Applications

- Labeling (Data Matrix Code, QR-Code, Logo, Text) of surfaces particularly glass or glass ceramics with visually attractive objectives

- forgery-proof labeling

- micro- and nano-structuring of surfaces, e.g. modification of reflection and transmission

- Product traceability, brand protection

Development Status

The method was successfully tested with different patterns on different surfaces:

- glass

- glass ceramics

- plastics

Current further development with regard to application in industry.

Patent Status

DE102015216342B3 (granted)

EP3341153A1 (granted)

US2018236596A1 (granted)

CN107921579A (granted)

KR20180098217A (disclosed)

Patent Applicant: Institut für Nanophotonik Göttingen e.V.

References

J. Meinertz, T. Fricke-Begemann, J. Ihlemann:

Micron and sub-micron gratings on glass by UV laser ablation

Physics Procedia 41, 701 (2013)

J. Bekesi, J. Meinertz, P. Simon, J. Ihlemann:

Sub-500-nm patterning of glass by nanosecond KrF-excimer laser ablation

Applied Physics A 110, 17 (2013)

J. Meinertz, A. Gödecke, L. J. Richter, J. Ihlemann:

Fast fabrication of diffractive patterns on glass by excimer laser ablation

Optics and Laser Technology, Volume 152, August 2022

J. Meinertz, L. J. Richter, C. M. Beckmann, J. Ihlemann:

Precision marking of glass with excimer lasers

PhotonicsViews, 2/2023

Contact

Dr. Maria Kamper

Patent Manager (Physics, Technology and Software)

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 (0) 551 30724 159

Ref: MM-1773-LLG

(Image Source Dr. Jürgen Ihlemann, IFNANO Göttingen e. V.)

Tags: Laser physics and optics