Commercial vehicle lightweight chassis

The non-driven and rigid utility vehicle chassis offers significant lightweight advantages, improved suspension properties and a built-in wheel alignment mechanism.

Challenge

Rising energy costs demand improved transport sector efficiency, which can be achieved with lightweight technologies. As the maximum admissible total weight of utility vehicles is legally restricted, chassis weight savings directly allow an increased potential payload capacity. Wheel alignment is one key factor for driving stability and tire wear. However, the chassis construction design is tied to certain boundary conditions. Mechanical requirements, such as resilience to bending moments (especially at the trailing arms) have to be fulfilled. Geometrical aspects, such as the placement of suspension elements, have to be met to keep ride height at a miminum. Weight savings by use of modern composite materials often fail due to high costs and available chassis designs. Further cost saving is achievable by minimizing production tolerances. However, this may require post-production chassis adjustments and bare significant additional costs.

Our solution

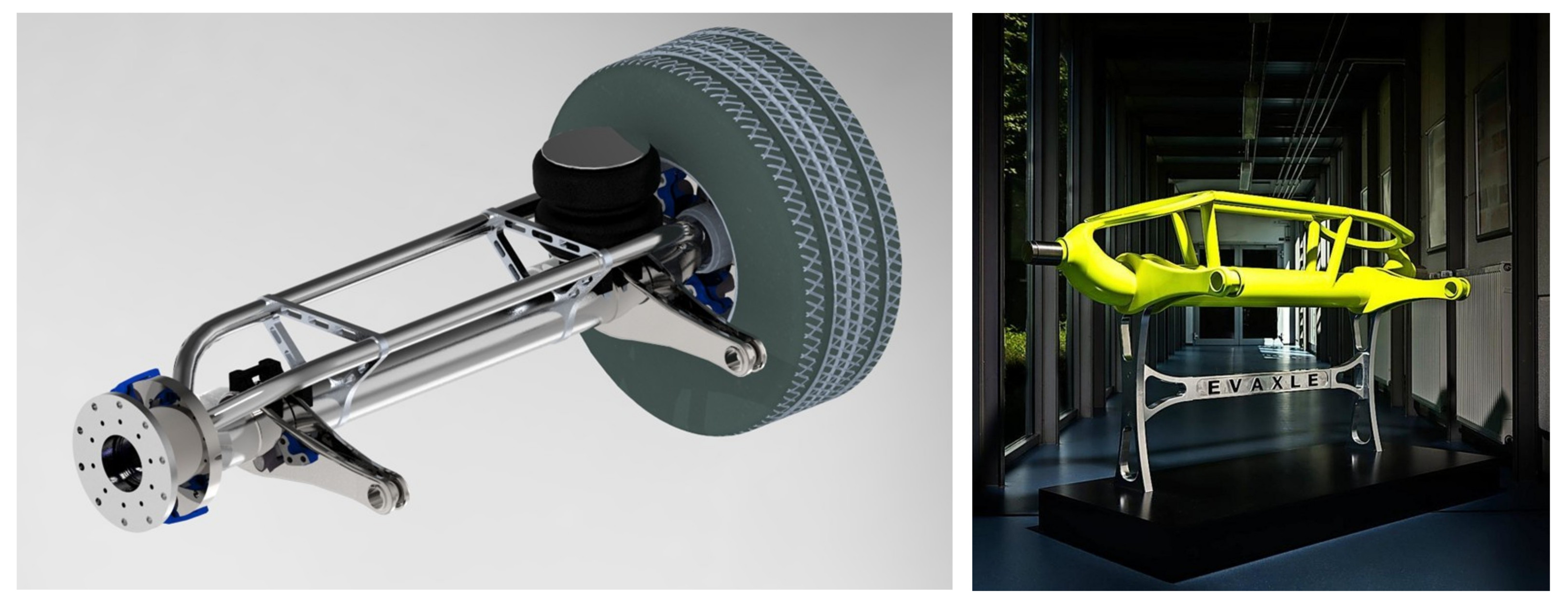

Prof. Frey and co-workers from the University of Applied Sciences Hildesheim/Holzminden/Goettingen (HAWK) have developed a rigid, non-driven, mechanically robust chassis for utility vehicles with an enormous lightweight advantage. The chassis structure comprises a lower and upper transverse strut, which are fixedly connected to each other by a connecting piece, wherein at least one of a brake flange and an axle trunnion is integrated into the connecting piece. The upper transverse strut exhibits two recesses, which limit the space located above the lower transverse strut. This space configuration is specifically designed for an advantageous accommodation of suspension elements, which are embodied as air suspension bellows. In a particular constructional layout, the axle body and the swinging arms of the chassis exhibit a skeletal design with a plurality of struts. In a side view the chassis structure has a L-shape, whereby one leg of the L is formed by a horizontal structural part forming the longitudinal swinging arms. The chassis design allows for a primarily pressure and tensile force transmission, while bending moments are mostly avoided. The ring-shaped upper braces allow the placement of suspension elements close or even directly above the axle, which leads to direct force transmission into the suspension, while the dropped lower brace keeps the overall height low. The commercial vehicle chassis structure is designed for a technical axle load of at least 7000 kg and comprises a mass of less than 130 kg.

Rigid and non-driven lightweight chassis for commercial vehicles according to the invention and patent applications (Source: Prof. Frey and co-workers from HAWK).

Rigid and non-driven lightweight chassis for commercial vehicles according to the invention and patent applications (Source: Prof. Frey and co-workers from HAWK).

Advantages

- Significant weight advantage compared to conventional chassis designs

- Production from carbon fiber-reinforced materials possible

- Energy and fuel savings due to lightweight construction

- Adjustable upper cross braces enable a cost-efficient built-in wheel alignment

- Increased payload due to low height and tare weight

- Optimized suspension properties through direct force transmission into the suspension

- Reduced wear due to minimized unsprung mass

Applications

- Trucks, trailers and busses

- Suitable for electric vehicles due to easy integration of electric motors close to wheel hubs

Development Status

System functionality tested. CAD drawings of all parts are available. A prototype is available.

Patent Status

US patent granted: US1220663B2

European patent granted: EP3257691A1

Chinese patent granted: CN107521300A

Patent holder: University of Applied Sciences and Arts Hildesheim/Holzminden/Goettingen (HAWK)

References

Press release: Light axle

Flyer IAA Commercial Vehicles 2018: Lightest 9to axle ever built

World premiere at IAA Commercial Vehicles 2018: Lightest 9to truck axle of its kind

Contact

Dr. Mirza Mackovic

Patent Manager Technology

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 (0) 551 30 724 153

Reference: CPA-1913-HAWK

www.sciencebridge.de

Tags: Automotive engineering, Physics and Technology & Software