Biobased adhesive formulation

A novel production method for a biobased adhesive, which comprises a tailored lignin structure as main component, is presented. The process technology overcomes the use of toxic phenol and formaldehyde, while the resulting adhesive exhibits superior physicochemical and mechanical properties.

Challenge

Phenol-formaldehyde resins are renowned representatives for the bonding of various materials (e. g. metals, wood, plastics, paper and rubber). They offer adequate mechanical properties at manageable costs. However, both chemicals (phenol and formaldehyde) are classified as toxic and are associated with serious health-related issues. Hence, alternative materials as adhesive components are highly desired. Technologies in relation to biorefineries are increasingly gaining attention, since they offer affordable solutions for the large-scale production of renewable and sustainable chemicals, materials and fuels. Lignin from biorefineries is still a part of the waste stream, which is used for energy generation by combustion. In the past decades lignin has partially or fully substituted phenol in phenol-formaldehyde wood adhesives, which highlights new avenues for advanced, biobased adhesive systems.

Our Solution

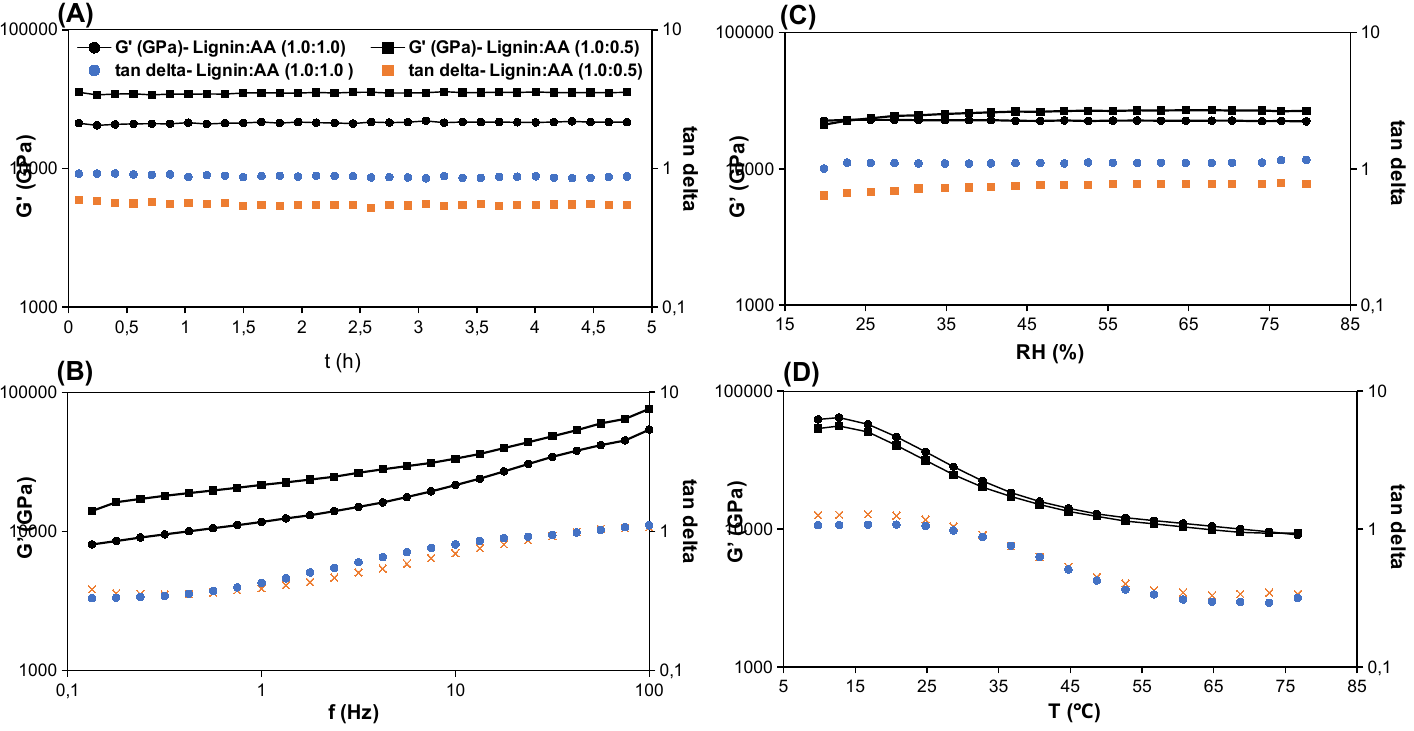

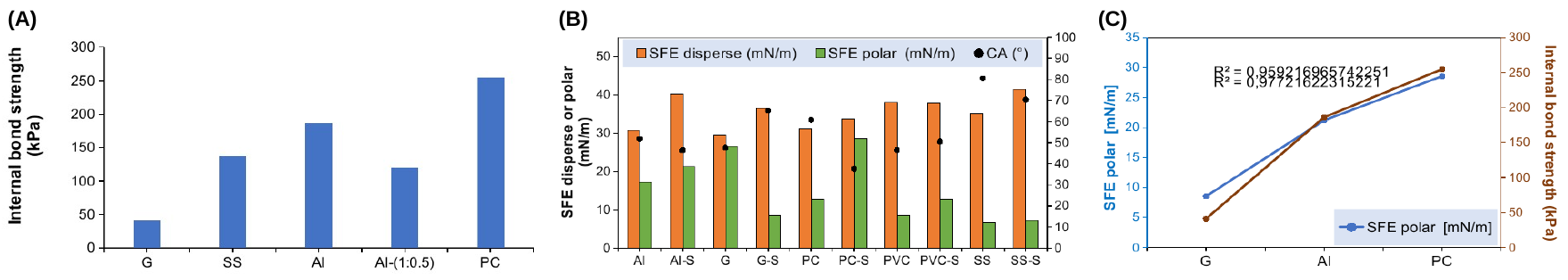

Scientists from the Georg-August-University of Göttingen have developed a novel method for the production of a phenol- and formaldehyde-free adhesive based on a functionalized lignin structure. Dimethylformamide and acrylic acid are used as functionlization agents. All components are eco-friendly and cause less/none health issues, which significantly simplifies the production and application of the related adhesive. Since the non-used or rather non-converted acrylic acid and dimethylformamide can be restored by destillation and reused, respectively, a more sustainable production route is possible. If applicable, sodium hydroxyde, which is used for adjustment of an alkaline medium, can be separated and lead back for the adhesive production. No waste incurs, since lignin can be utilized. Moreover, the adhesive can be used directly after its production, without further processing steps (e. g. fractionation or depolymerization). Preferentially, the lignin structure can be cross-linked, which results in an increased adhesion and mechanical performance of the adhesive. Fig. 1 and 2 show some key characteristics of the adhesive according to the invention.

Fig. 1: Mechanical analysis of the lignin-based universal adhesive. Storage modulus (G’) and tan delta (loss factor) as function of a) time (t), b) relative humidity (RH), c) frequency (f) and d) temperature (T). The results are obtained from dynamic mechanical thermal analysis and shown for different lignin/acrylic acid (AA) ratios. Data according to patent application. Reprinted (adapted) from S.K. Singh et al., Green Chemistry 24 (2022) 2624 – 2635. Copyright The Royal Society of Chemistry 2022.

Fig. 2: Characteristics and properties of the biobased adhesive: A) internal bond strength, B) cumulative surface energy (SFE) and contact angle (CA) and C) SFE and internal bond strength as function of different materials. Data are shown for the following materials and their combinations: glass (G), stainless steel (SS), aluminium (Al), polycarbonate (PC) and polyvinyl chloride (PVC). Data according to patent application. Reprinted (adapted) from S.K. Singh et al., Green Chemistry 24 (2022) 2624 – 2635. Copyright The Royal Society of Chemistry 2022.

Advantages

- Universal, eco-friendly and (in terms of health) harmless adhesive

- No additional processing (e. g. fractionation and depolymerization) required

- Sustainable process technology and production

- Good physicochemical and mechanical properties

Applications

- Bonding of various materials (e. g. wood, glass, metals and plastics) possible

- Use in the manufacturing/processing of wood, plastics and metal components conceivable

- Electronic and electrical components

Development Status

The production method has been successfully developed on kilogram scale. The physicochemical and mechanical properties of the adhesive have been successfully approved.

Patent Status

German and PCT patent applications are filed

Application number: DE102022103784.3

Patent holder: Georg-August-University of Göttingen public law foundation

Contact

Dr. Vanessa Jensen

Patent Manager Lifescience

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 551 30724 149

Reference: BioT-2388-SUG

Tags: Synthesis and Process Technology, Chemistry, Physics and Technology & Software