Micro-structured black titania surfaces

We present a new technology which leads to the development of surface micro structures and a black appearance of Ti containing, commercially available glasses by irradiation with an excimer laser (ArF laser with 193 nm wavelength and 20 ns pulse duration). The technology can be accomplished in a standard air environment and does not require vacuum or inert gas.

Challenge

Meanwhile, lasers are frequently used for processing glasses, for example, to make markings, change the wettability of materials, create self-cleaning surfaces or make optical adjustments such as anti-reflective coatings or waveguides. Specifically, laser-induced periodic surface structuring on glasses using femtosecond (fs) lasers is part of the state of the art in this context. To date only ordered mound-like structures of rutile crystalline phases could be generated on glasses using longer nanosecond (ns) laser pulses. However, this requires specially titanium oxide (TiO2)-coated surfaces. Additionally, for this processing an inert gas atmosphere and comparatively high laser intensity are necessary.

Our solution

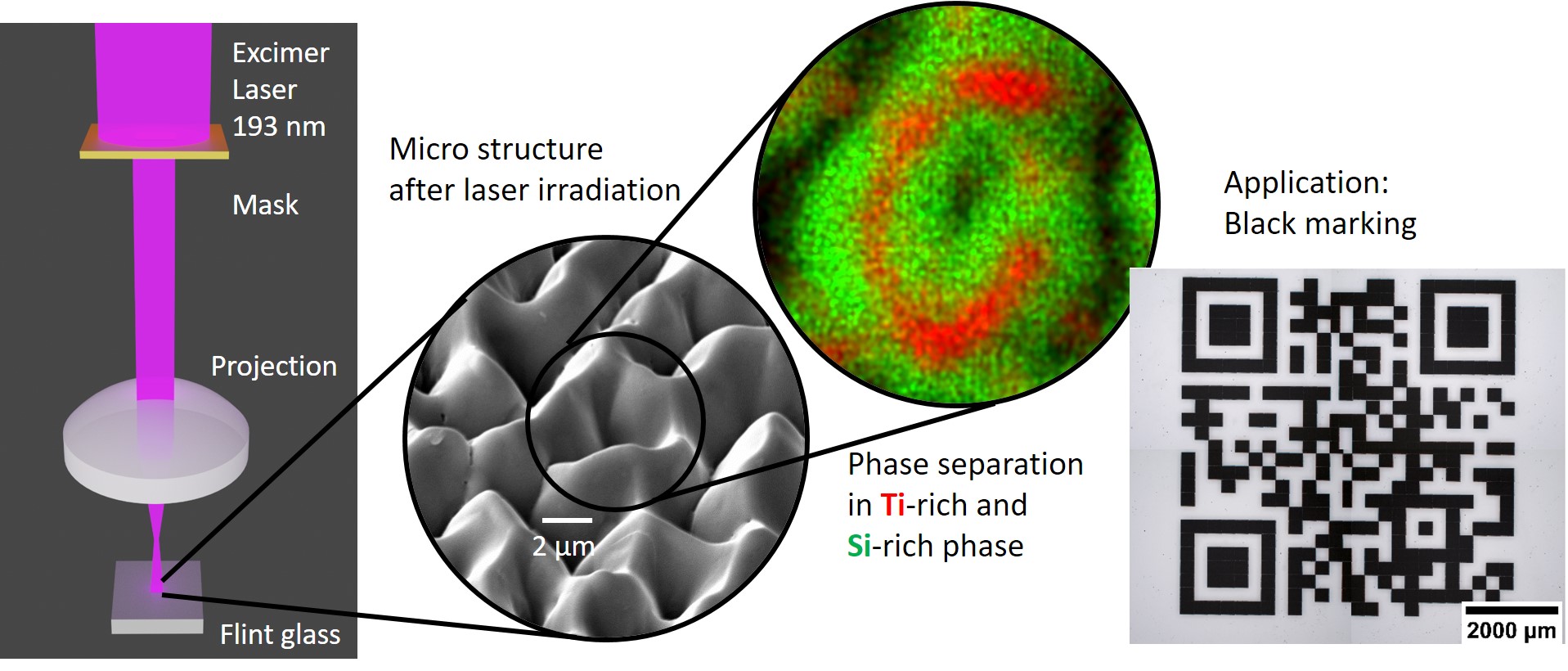

The technology describes a marking technique of titanium oxide-containing glasses using excimer laser radiation (ArF laser with 193nm wavelength and 20ns pulse duration) in ambient air. Specifically, the irradiation of the glasses takes place in an optical setup that images a predetermined mask onto the surface of a sample. Laser pulses that are only nanoseconds long and have intensity or fluences below the material dependent ablation threshold are used to induce phase separation on the surface of the glass. Surface studies showed that upon illumination, phase separation into a silicon and titanium rich phase occurs near the surface. The dark appearance is due to light scattering from the resulting microstructure and the partial reduction of the titanium oxide. The markings can be realized with high resolution and high contrast while using comparatively low laser intensity below the ablation threshold. It is possible to implement a wide variety of markings.

Scheme of laser irradiation experiments (left), scanning electron microscope image of laser induced surface modification and corresponding element mapping (middle), microscope image of a QR-code made by laser modification of Ti- containing glass (193 nm, 300 mJ/cm2, 200 pulses/pixel) – application example (left). ( source: Dr. Jürgen Ihlemann, Institut für Nanophotonik Göttingen e.V).

Scheme of laser irradiation experiments (left), scanning electron microscope image of laser induced surface modification and corresponding element mapping (middle), microscope image of a QR-code made by laser modification of Ti- containing glass (193 nm, 300 mJ/cm2, 200 pulses/pixel) – application example (left). ( source: Dr. Jürgen Ihlemann, Institut für Nanophotonik Göttingen e.V).

Advantages

- High contrast marking technique

- Compact and easy to build up setup

- Possible at ambient air conditions

- Comparably low laser power necessary

Applications

- Marking or inscription of any type of glass or coating containing titanium oxide, e.g. lenses (glasses) or beverage glasses with the purpose of identification, product traceability and as a quality feature

- Markings serving as crosshairs or scales

- Decorative purposes

- Marking of self-cleaning building facades which use titanium oxide coatings on glass

Image source: Dr. Jürgen Ihlemann, Institut für Nanophotonik Göttingen e.V

Development status

Proof of concept shown in the lab

Patent status

Institut für Nanophotonik Göttingen e.V.

E102022107151.0 (filed)

References

Contact

Dr. Maria Kamper

Patentmanager Physics, Technology and Software

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 551 30724 159

Reference: MM-2337-LLG

Tags: Laser physics and optics, Physics and Technology & Software