Preconnection element for the protection of hollow fibers

This invention is a further development to the flexible hollow fiber for pulse compression which was also developed at the Institut für Nanophotonik Göttingen e.V. (see Ref.: MM-2010-LLG). When laser light is coupled into hollow fibers, the problem often arises that parts of the light distribution can penetrate the thin wall (50-300 μm) and damage it by erosion/ablation/melting. This preconnection element provides a solution approach.

Challenge

Gas-filled hollow fibers are well-known components for spectral broadening of ultrashort pulses in order to be able to to compress them further. In order to ensure the necessary straightness of the flexible hollow fibers at nearly any lengths, a new approach for stretching the fibers has been developed in the past (see technology Flexible hollow fiber for pulse compression with reference MM-2010-LLG). In practice, when laser light is coupled into hollow fibers, the problem often arises that parts of the light distribution can penetrate the thin wall (50-300 μm) and damage it by erosion/ablation/melting.

Our solution

To counteract this problem, a new type of preconnection has recently been developed to reliably protect hollow fibers from damage by strong light fields during coupling. The preconnection element is also designed in such a way that it can be quickly and easily replaced or reworked if it is damaged. This novel solution will make it possible to safely transport medium powers of up to 1 kW through a thin-walled hollow fiber. This requires not only effective protection of the fiber input, but also effective cooling to dissipate the excess energy. In addition, the modularity of the hollow fiber device has been increased to meet the requirements of the industry. The invention is based on the finding that the diameter of the freely propagating beam behind the exit aperture of a hollow fiber with the usual inner diameter (> 250 µm) does not change appreciably in the first few tenths of a millimeter. Therefore, “interruption” of the hollow fiber by a small air gap (of up to a few mm) does not result in any appreciable impairment of the beam propagation properties. In this way, two separate sections can be placed one behind the other, whose axes must of course be very precisely adjusted coaxially. For virtually undisturbed optical functionality, only the inner diameters of the two sections must be matched. The outer diameters, on the other hand, are freely selectable. Thus, two hollow fibers can be coaxially connected in series, with the second being a longer hollow fiber and the first piece in front in the beam direction being a thick-walled hollow fiber with a short length (2-5 mm). The thick-walled preconnection element is much more durable than thinner-walled components due to its robustness against ablation or erosion on the front surface. In addition, due to its modular design, it can be replaced relatively easily, thereby significantly extending the lifetime of the entire hollow fiber.

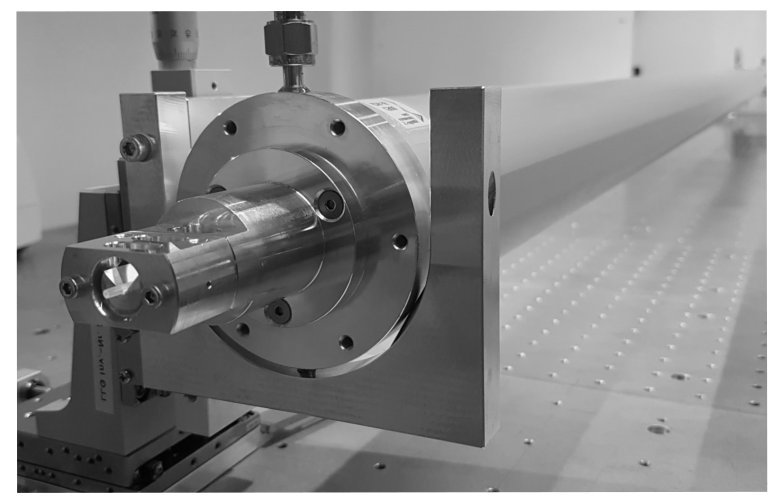

Preconnection element with a thick-walled exchange fiber for protection of the whole hollow fiber. (source: Dr. Peter Simon, Institut für Nanophotonik Göttingen e.V.)

Preconnection element with a thick-walled exchange fiber for protection of the whole hollow fiber. (source: Dr. Peter Simon, Institut für Nanophotonik Göttingen e.V.)

Advantages

- Further development of a flexible thin hollow fiber setup to protect it from damage by strong light fields during coupling

- Enables the safe transport of medium powers of up to 1 kW through a thin-walled hollow fiber

- Thick-walled preconnection is more durable against ablation or erosion

- Preconnection is easily replaceable

- Increases the lifetime of the entire hollow fiber

- High modularity

Applications

- Preconnection element for flexible hollow fibers

Development Status

Preconnection successfully tested and added to hollow fibers, coupling of 1 kW into fibers achieved, modularity increase for industrial applications

Patent Status

Institut für Nanophotonik Göttingen e.V.

DE102018126791A1 (granted)

References

Contact

Dr. Maria Kamper

Patent Manager Physics & Technology

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 551 30724 159

Reference: CPA-2091-LLG

Tags: Laser physics and optics, Physics and Technology & Software