Extraction system for brake dust and tire wear

The innovative systems can efficiently extract the fine dust particles generated by vehicle disc brakes and tire wear. This can help to reduce the amount of particulate matter released into the environment.

Challenge

About 85% of the traffic-related particulate matter is formed by tire, brake and road abrasion as well as by the whirling up of the dust layer on the roadways. Brake dust is classified as hazardous to health and is particularly dangerous in the air we breathe. In general, exhaust from Diesel and gasoline engines is regulated by European exhaust norms, which currently do not include brake dust. However, recent reports indicate that the reduction of brake dust generated by vehicles will become mendatory in near future. Due to the nature of brake discs and pads, the brake dust particles can contain extremely harmful substances (for example nickel, chromium and copper). Currently available active systems for brake dust collection usually worsen the energy balance of the vehicle and may be inefficient. Available passive filter solutions cannot efficiently break the boundary layer near the brake disc, which can have a negative impact on the brake dust filtering. The filter hood enclosure can increase the thermal load on the brake disc, which is detrimental to durability and safety.

Our solution

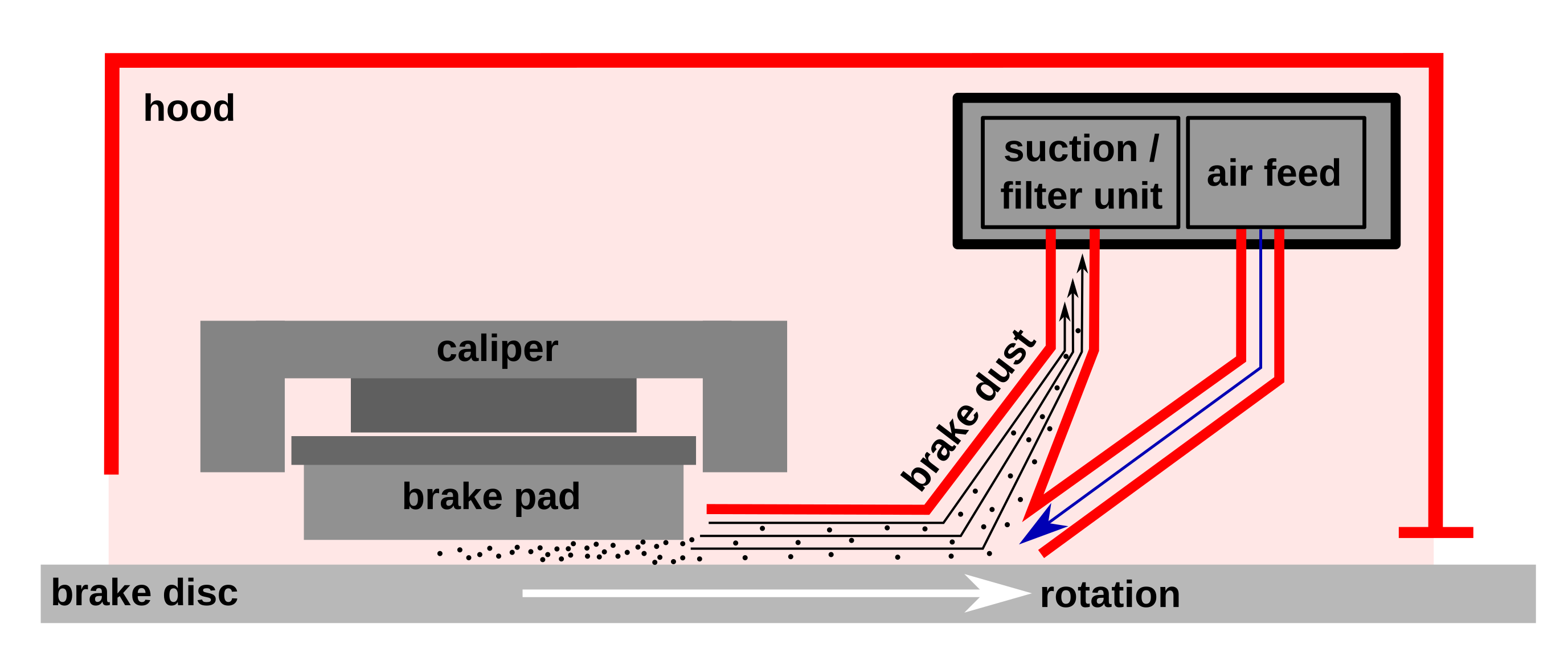

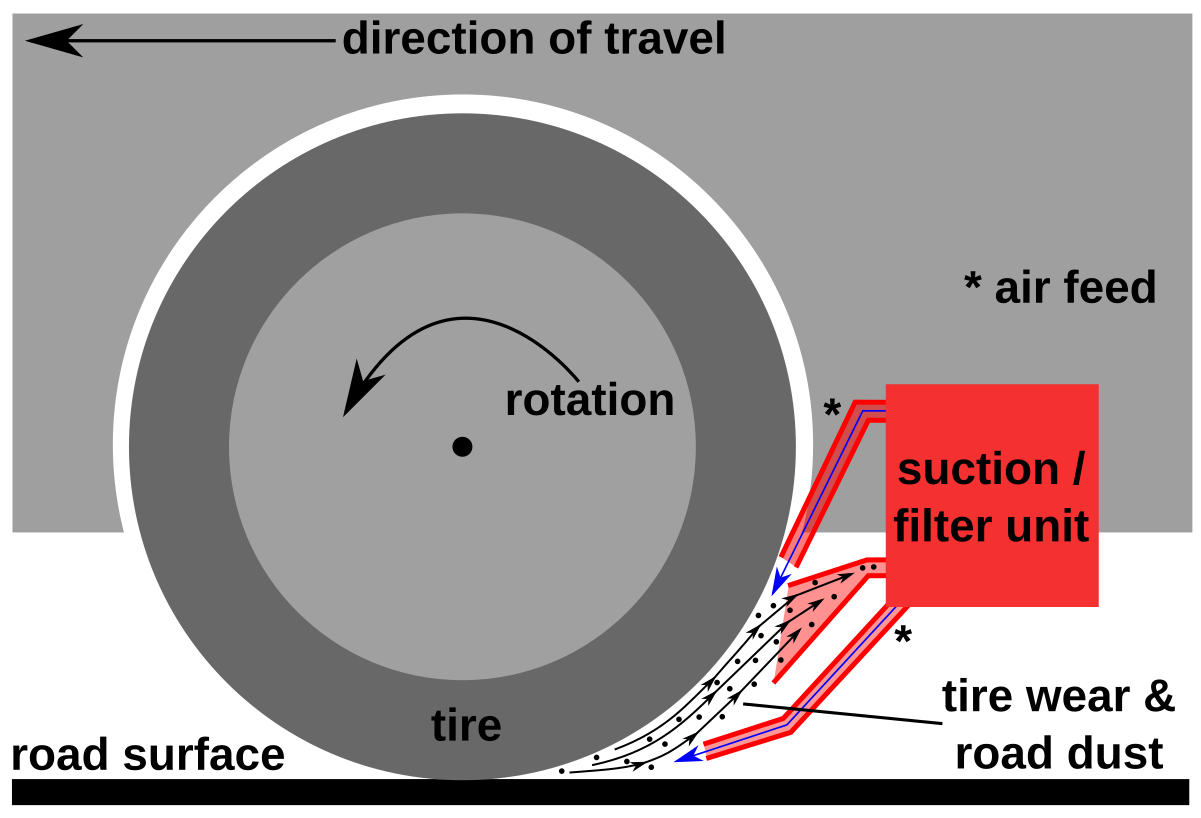

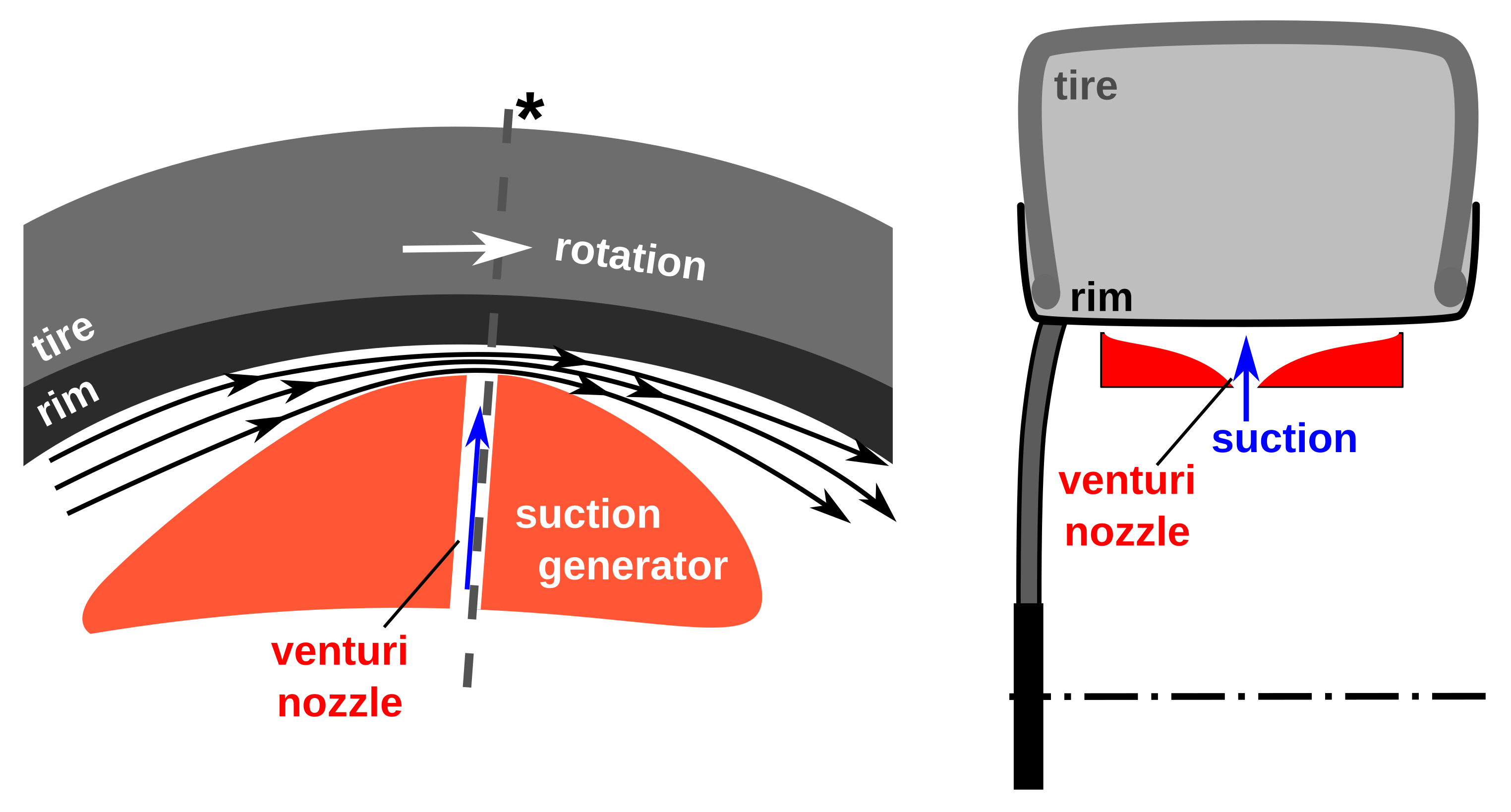

A scientist from the Ostfalia University of Applied Sciences has developed extraction systems for brake dust and tire wear generated by vehicles. The systems have an air injection system to remove the boundary layer contaminated with fine dust particles. In combination with a hood, a more comprehensive and energy-efficient extraction of the dust layer is possible. According to the invention, the negative pressure required for efficient suction is relatively low. The required vacuum is not generated by additional consumers (e.g. pumps and turbines), but with the help of a vacuum generator based on the Venturi effect. The vacuum generator is positioned in the form of an air deflector near the inner rim edge of a vehicle wheel. This leads to a narrowing of the flow cross-section for the boundary layer of the rotating wheel forming at the inner edge of the rim at the most narrow point. Thus, a vacuum corresponding to the speed is always available during the journey, which is sufficient to operate the extraction devices. By providing the right amount of feed and suction volume flow, a complete collection of the brake dust particles into the filter is possible.

Figure 1: Extraction system for brake dust (source: Prof. Klinge, Ostfalia University of Applied Sciences Wolfenbüttel/Braunschweig, Germany).

Fig.2: Device for the extraction of tire wear (source: Prof. Klinge, Ostfalia University of Applied Sciences Wolfenbüttel/Braunschweig, Germany).

Fig.2: Device for the extraction of tire wear (source: Prof. Klinge, Ostfalia University of Applied Sciences Wolfenbüttel/Braunschweig, Germany).

Fig.3: Vacuum generator (source: Prof. Klinge, Ostfalia University of Applied Sciences Wolfenbüttel/Braunschweig, Germany).

Fig.3: Vacuum generator (source: Prof. Klinge, Ostfalia University of Applied Sciences Wolfenbüttel/Braunschweig, Germany).

Advantages

- Efficient and effective capture of the particulate matter without contact to moving parts

- Suction with relatively low negative pressure possible

- Up to 100% extraction of the flow loaded with dust particles can be realized

- High energy efficiency due to passively generated negative pressure close to the consumer

- No negative influence/impact on the cooling properties of the brake disc

- Suitable for internally ventilated disc brakes

- Retrofit option available

Applications

- Passenger cars

- Trucks and busses

- Motorcycles/two-wheelers

- Rail vehicles

Development Status

Functionality has been successfully tested. Design drawings available. Prototype development planned.

Patent status

German patent applications:

DE102019133794A1

DE102019133772A1

Patent holder:

Ostfalia University of Applied Sciences – Hochschule Braunschweig/Wolfenbüttel (Germany)

Related Technologies

Contact

Dr. Mirza Mackovic

Patent & Innovation Manager Technology

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: +49 (0) 551 30 724 153

References: MM-2179-FHBW and MM-2184-FHBW

www.sciencebridge.de

Tags: Automotive engineering