High-precision microCT phantom

Phantoms suitable for micro computed tomography (microCT) can be produced either in high resolution or with defined contrast. This technology describes the production of microCT phantoms characterized by adjustable X-ray contrasts which can be printed in various high-resolution 3D structures.

Challenge

MicroCT is an established method for the radiological examination of biomedical samples. The X-rays pass the specimen, which causes an attenuation of the intensity relative to the local electron density. The 3D distribution of the underlying electron distribution can be reconstructed from the angle-dependent attenuation data obtained in this way. X-ray contrast not only determines the visibility of structures, but is also an important factor in clinical diagnostics. Contrast is usually expressed in Hounsfield units, and the Hounsfield scale allows a wide range of materials and fabric types to be identified according to relative contrast. The reference values are water (0 HE) and air (-1000 HE). Materials with similar attenuation are difficult to differentiate. A phantom is an optically visible object structure, e.g. a replica of a body part (bones and organs) or geometrically regular measuring structures (e.g. cylinders filled with water, air, calcium phosphate-based powders or contrast agents). For high-resolution microCT, phantoms made of spatially homogeneous materials are required in order to avoid grainy distortions (Fig.1). Until now, resolution and contrast have always had to be considered separately in the microCT system.

Our Solution

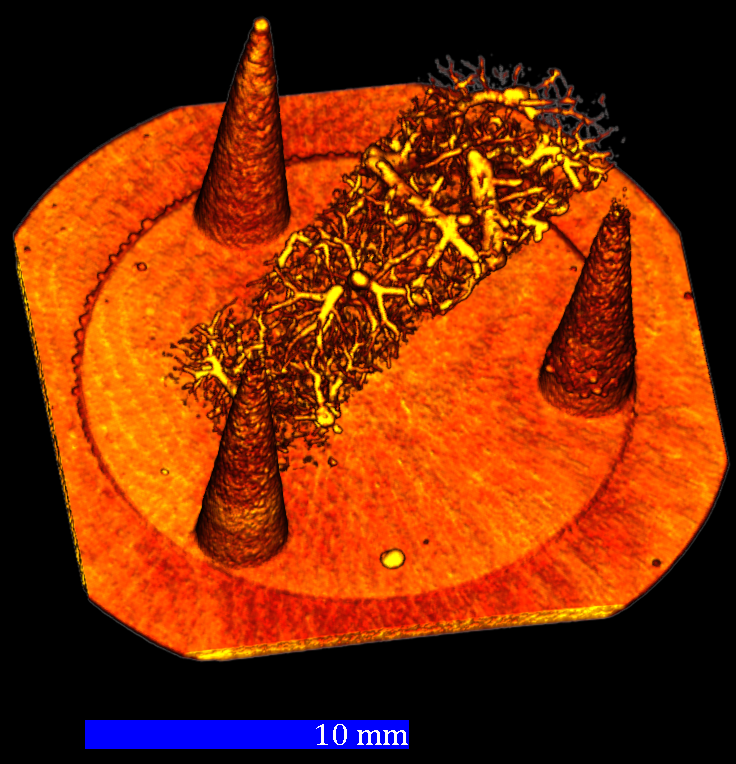

A high-precision microCT phantom is created with a mixture of UV-light polymerized resin and iodine contrast agent. 3D structures with a resolution of <50µm can be printed using various methods. Figure 2 shows a cone phantom printed in stereolithography (SLA) with lung tissue embedded in resin. It is even possible to print phantoms with complex 3D structures and changing contrast in high resolution using the PolyJet printing process.

Fig. 1) Comparison of a microCT contrast phantom printed using the proprietary process and a commercially available microCT contrast phantom.

Fig. 1) Comparison of a microCT contrast phantom printed using the proprietary process and a commercially available microCT contrast phantom.

Advantages

- Adjustable X-ray contrast in polymerized synthetic resin objects

- When using SLA printing or PolyJet printing, high-resolution structures in the range (<50µm) can be printed

- Production of standards for calibrating a CT, whereby both the shape and the X-ray contrast can be defined

- Production of markers for the geometric analysis of samples

- Production of form and X-ray contrast replicas of tissue samples

- Embeddability in all common matrix materials for histological examination

- Significantly more cost-effective production compared to Binder Jetting or Selective Laser Sintering (SLS) printing

Applications (in h2)

Micro computed tomography is widely used in both clinical and industrial 3D imaging. The use of micro CT phantoms enables the evaluation of a wide range of image quality parameters of special micro CT systems. MicroCT phantoms help to determine the scanning properties, quality assurance and testing of the consistency and reproducibility of the system. Using resin-based 3D printing techniques, these customized micro CT phantoms can be produced quickly and cost-effectively.

Fig. 2) Lung tissue embedded in synthetic resin with printed radiopaque conical phantom.

Fig. 2) Lung tissue embedded in synthetic resin with printed radiopaque conical phantom.

Development Status (in h2)

Successfull production of high-resolution 3D X-ray phantom with defined X-ray opacity.

Patent Status (in h2)

IP rights (DE 10 2024 105 696.7) have been filed in the name of the Hochschule für angewandte Wissenschaft und Kunst Hildesheim/Holzminden/Göttingen and the Georg August Universität Göttingen Stiftung Öffentlichen Rechts, Universitätsmedizin and a licensing partner is sought.

References (in h2)

Nolte, P., Brettmacher, M., Gröger, C.J. et al. Spatial correlation of 2D hard-tissue histology with 3D microCT scans through 3D printed phantoms. Sci Rep 13, 18479 (2023). https://doi.org/10.1038/s41598-023-45518-0

Contact

Dr. Vanessa Jensen

Patent Manager Life Science

E-Mail: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Tel.: +49 551 30724 149

Reference: BioV-2489-HAWK

Tags: Computer tomography, Diagnostic