Flexible hollow fiber for pulse compressors

A stretched flexible hollow fiber is proposed as a waveguide in high-energy pulse compressors. This approach leads to superior straightness virtually independent of the fiber length. It is particularly well suited for fibers with inner diameters much larger than the wavelength, where the main limitation for the fiber length is losses due to undesired fiber bending.

Challenge

To generate ultrashort, few-cycle laser pulses, ultra-broadband radiation is necessary. Since no gain material has a sufficiently broad gain bandwidth, nonlinear spectral broadening methods have to be applied to the amplified pulses. This is especially important in the UV spectral range, because the gain materials available in this region do not support the amplification of pulses shorter than 100 fs. The spectral extension of high-energy laser pulses is usually achieved by self-phase modulation in noble gases filled into a hollow waveguide. A crucial point of the technique is that the hollow fibers are multimode waveguides and the refractive index of the core material (noble gas) is smaller than that of the cladding (fused silica); therefore no total internal reflection occurs at the interface. As a result the wave guiding is not as strong as in conventional fibers, leading to larger propagation losses that limit the nonlinear interaction length. Furthermore the losses of the fundamental mode are increasing more rapidly than those of the higher-order modes by bending the fiber. Technical issues, among others, limit the fiber length to ∼1 m in most of the practical case.

Our solution

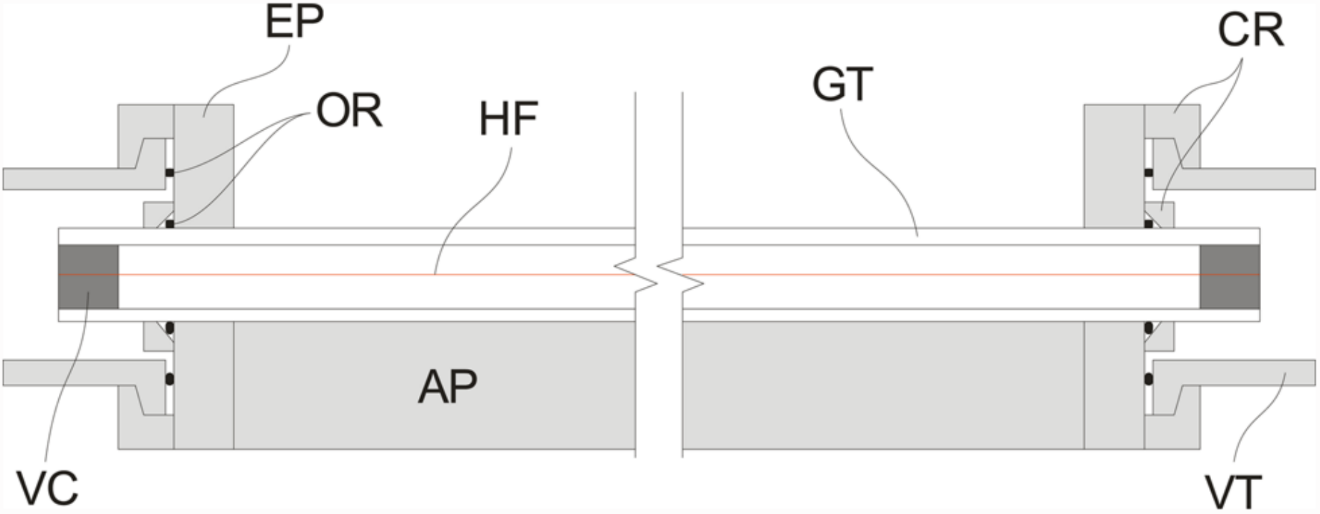

The inventors introduced an alternative approach to the usage of rigid hollow fibers by using stretched flexible hollow fibers as waveguides, which allows using much longer fibers than in previous setups without introducing considerable bending losses. There is a demand for the compression of higher energy pulses. Taking the properties of the available noble gases into account, the compression of pulses of several millijoules in the UV and several tens of millijoules in the IR seems possible. In these cases the cross section of the fiber has to be increased considerably due to the ionization issues, which leads to a rapid decrease of the propagation losses, enabling the use of considerably longer fibers. Furthermore to prevent nonlinear effects in front of the waveguide, it is desirable to apply a pressure gradient along the capillary, which, by reducing the effective interaction length, also demands for longer fibers. These ideas resulted in a fiber unit presented in the figure below. The construction allows the application of a pressure gradient between the two ends of the fiber, which is advantageous for the compression of high-energy pulses, because it allows us to evacuate the focal region in front of the fiber leading to an optimized beam launching by preventing defocusing effects due to ionization. In the course of manufacturing, the capillary is fed through the glass tube and pulled by a force of 10–15 N. The supporting glass tube assembly is oriented so it does not touch the stretched capillary over its entire length. The waveguide is then glued into the tube at both ends over a length of ∼10 mm by epoxy glue. After curing, the fiber is cut within the glued regions by a diamond tool. Since the support only holds the fiber at the two ends, it is not necessary for the support to be straight; it is enough to maintain a constant shape during and after the gluing process. The feasibility of the approach was experimentally tested on a 3 m-long unit, and the results show that its transmission reaches the theoretical limit and the beam emerging from the fiber is found to be diffraction limited. A further test confirmed that considerable spectral broadening can be achieved by the newly designed fiber assembly. The proposed method is also well-suited to the implementation of a pressure gradient in the hollow fiber. Because of its attributes and scalability, the stretched flexible capillary waveguide opens new perspectives for the compression of multi-millijoule laser pulses, especially in the UV spectral range where increasing the fiber lengths gives substantial advantages.

Fiber unit consisting of: Fiber assembly. HF, hollow fiber; GT, glass tube; VC, vacuum-tight cement; AP, supporting aluminum profile; EP, end plate; OR, O-ring; CR, clamping ring; VT, vacuum tubing. (source: Dr. Peter Simon, Institut für Nanophotonik Göttingen e.V.)

Fiber unit consisting of: Fiber assembly. HF, hollow fiber; GT, glass tube; VC, vacuum-tight cement; AP, supporting aluminum profile; EP, end plate; OR, O-ring; CR, clamping ring; VT, vacuum tubing. (source: Dr. Peter Simon, Institut für Nanophotonik Göttingen e.V.)

Advantages and Applications

- Free scalability of fiber length combined with high transmission

- Allows compression of higher energy laser pulses

- Diffraction limited output beam

- Opens new perspectives for the compression of multi-millijoule laser pulses, especially in the UV spectral range

Development Status

Process successfully tested and several improvements added (see additional technology portfolio: CPA-2091-LLG, MM-2314-LLG)

Patent Status

Institut für Nanophotonik Göttingen e.V.

DE102007048769B3 (granted)

References

T. Nagy et al. - Appl. Opt. 47.18: 3264-3268 (2008)

T. Nagy et al. - Optica 6.11: 1423-1424 (2019)

Contact

Dr. Maria Kamper

Patent Manager Physics & Technology

E-Mail: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Tel.: +49 551 30724 159

Reference: MM-2010-LLG