Sustainable compounds for efficient flotation purification processes

The technology comprises switchable materials for selective and efficient flotation purification processes, which are specifically tuned for the recycling of electronics and mineral processing.

Challenge

Technical products used in everyday life contain valuable elements such as lithium, gold or so-called critical raw elements, which are not infinitely available or difficult to access. The worldwide increasing demand for electronics also results in increasing electronic waste stemming from products reaching the end of their lifetime. Electronic products like cell phones can contain 50 – 60 different elements, which are in worst case thrown away or discarded after their lifetime. Hence, recycling technologies are highly attractive, also in relation to the production of refurbished and recycled electronic products. Recycling technologies may involve a flotation process, which is characterized by separation of elements or element mixtures from undesired materials. Flotation is based on surface hydrophobicity of dispersed particles. Available separation technologies and their efficiencies may strongly depend on flotation mixtures, which often need to be tuned to the present separation challenge. Process technology efforts may increase, since new flotation systems need to be developed continuously, in order to be adapted to certain elemental selectivity. This can result in significant technological and economical drawbacks.

Our Solution

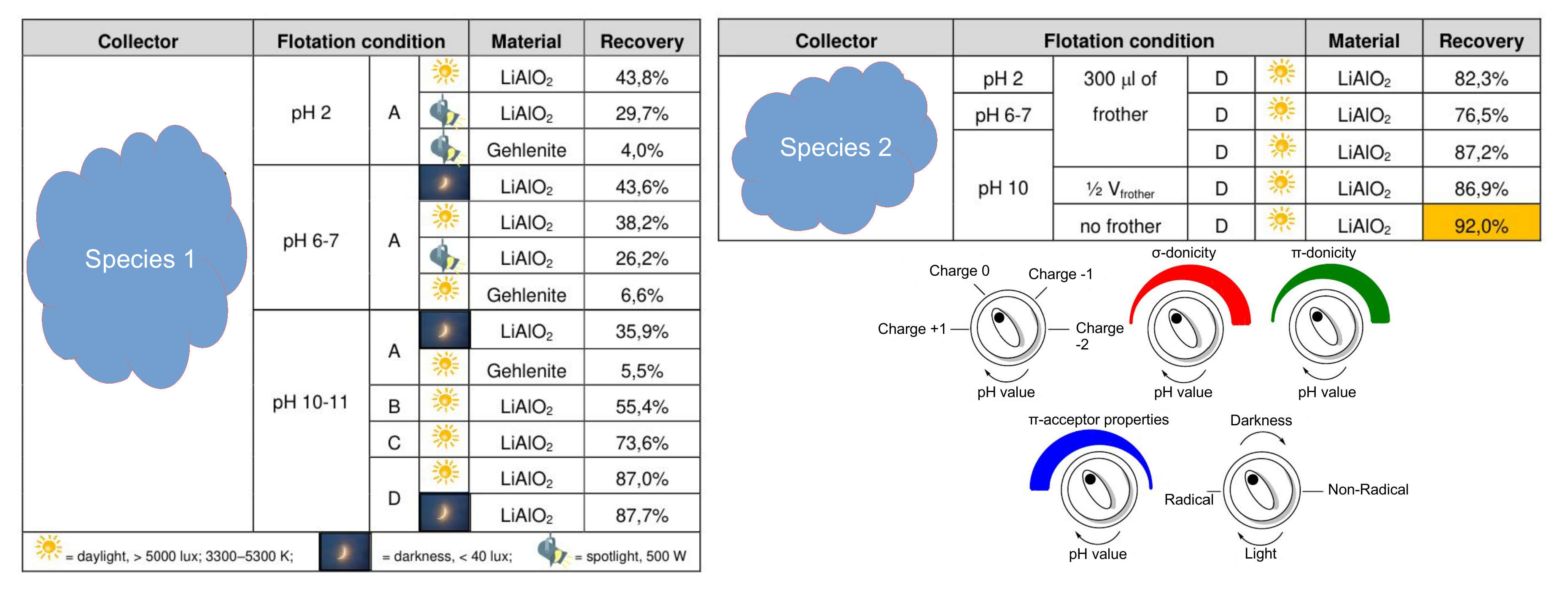

Scientists from the Clausthal University of Technology have developed switchable materials in combination with a highly reproducible process technology, which enables selective and efficient flotation purification processes. The compounds are robust, stable and based on natural and renewable resources. Substituted and unsubstituted species can be used as collector or suppressor, depending on the desired flotation conditions. The flotation purification efficiency can be adapted by collector selectivity based on parameters such as pH value, light conditions, temperature and additives. While source of light can be used to produce radical species, the absence of light can prevent their formation, leading to a different flotation outcome. Addition of radical-producing additives can affect the flotation time. Selective flotation of lithium minerals can be carried out in the range of room temperature, while specific temperatures below or above room temperature are possible.

Example for the selective flotation of lithium aluminate and gehlenite according to the present invention and patent application (source: Prof. Schmidt, Clausthal University of Technology).

Example for the selective flotation of lithium aluminate and gehlenite according to the present invention and patent application (source: Prof. Schmidt, Clausthal University of Technology).

Advantages

- Natural, renewable and low cost resources

- Sustainable materials

- Robust, stable and switchable compounds

- Selective, reproducible and efficient flotation purification technology

- Flexible operation mode

- High recovery rates

- Highly adaptable flotation system (no need for preparation of new or additional flotation systems)

- Low cost system set-up

Applications

- Mineral processing (element extraction from natural resources)

- Recycling of electronics (e.g. batteries)

- Wastewater treatment

Development Status

The technology is efficient and reproducible on laboratory scale. Process scale-up in development.

Patent Status

German patent application: DE102023135397.7

Patent holder: Clausthal University of Technology

Contact

Dr. Mirza Mackovic

Patent & Innovation Manager Technology

E-Mail: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Tel.: +49 551 30724 153

Reference: CPA-2407-T290

Tags: Chemie, Nanotechnologie, Physik und Technik & Software