Superimposed CGHs on metals using laser ablation of diffractive pixels

A special interference process allows the fabrication of computer-generated holography (CGH) as carrier of information which can’t be recognized with the human eye. The CGHs consist of N * M pixels which, when illuminated with coherent light, generate an imagine with the same pixel dimensions in a Fourier plane that can be viewed on a screen or with a CCD chip. Several CGHs can be written on the same area. When illuminated with the same coherent reading beam, they appear separately in different directions (diffraction orders) and can be read out.

Challenge

If an ordinary CGH is illuminated with a laser reading beam, the image is formed in the direction of the light reflected from the surface (0th order). In the case of a binary CGH, two point-mirrored images are created in this way. If several CGHs are to be generated and read out in a very small space, with all CGHs being illuminated simultaneously with the same reading beam, this is not possible in the conventional way. The reason for this is that the different images of the different CGHs are all formed in same the direction of the reflected beam in the 0th order and overlap there.

Our solution

By direct interferometric laser ablation, the individual pixels of the CGH are generated in such a way that all pixels contain a diffractive substructure consisting of linear gratings of the same period, which diffracts incident light in defined directions. Each individual CGH is assigned a specific type of substructure. This can be a different period of the grid lines or in the simplest case a different orientation of the grid lines. The individual pixels of the CGH are arranged locally in such a way that they do not overlap. This can be done by dividing the targeted writing area into larger pixels, which in turn are subdivided into subpixels, each subpixel being assigned to a particular CGH. Alternatively, the individual CGHs can be written very close to each other so that they do not overlap but can still be illuminated with the same readout beam. This method has been successfully tested in practice. With the diffractive laser scanner developed at IFNANO, five different CGH were written close to each other in one process step. The pixels of the CGH had a diffractive substructure of linear gratings with a grating period of 1.5 µm. Each of these CGH generates an image in the focal plane of the illumination beam in the direction of the 0th order as well as in the +- 1st and higher diffraction orders of the diffractive substructure. If the orientation of the grating lines is varied for each CGH, all images of the CGH still overlap in the 0th order, but separate in the first and higher diffraction orders.

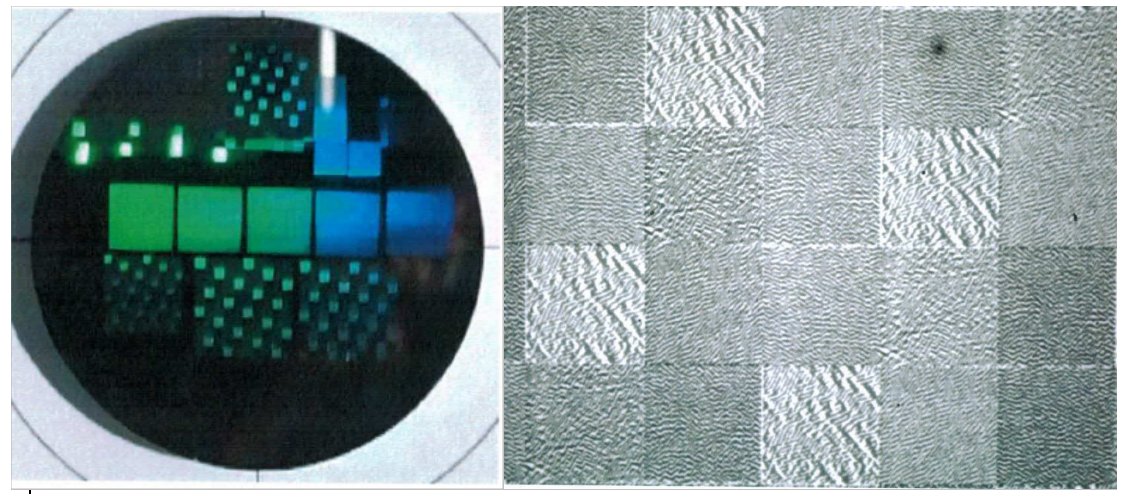

Five individual CGHs were written very close to each other so that they do not overlap but can still be illuminated with the same readout beam.. (source: Jan-Hendrik Klein-Wiele, Institut für Nanophotonik Göttingen e.V.)

Five individual CGHs were written very close to each other so that they do not overlap but can still be illuminated with the same readout beam.. (source: Jan-Hendrik Klein-Wiele, Institut für Nanophotonik Göttingen e.V.)

Advantages

- Diffractive surface structure which hides a holographic image withing

- Only visible when irradiated with coherent light (laser)

- Therefore impossible to discover without special optics and thereby hard to fake

- Diffractive appearing surface structures have a nice color shine of high aesthetics

- Virtually endless combinations possible

- Can be also used as design object visible with the eye with a hidden holographic code inside

- Impossible to forge but distinctively identifiable

Applications

- Forgery protection by unique and individual marking of products

- Flexible implementable holograms (company logos, serial numbers etc.)

- Colorful design object with implemented security feature for forgery protection

- Read-out with e.g. plug-in devices for a mobile phone (compact laser light source and camera)

Development Status

Process successfully tested on metal surfaces

Patent Status

Institut für Nanophotonik Göttingen e.V.

DE102018119706A1 (disclosed)

References

Contact

Dr. Maria Kamper

Patent Manager Physics & Technology

E-Mail: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Tel.: +49 551 30724 159

Reference: CPA-2050-LLG