Novel technology to predict iron clogging and corrosion in water and hydraulic systems

Corrosion and iron clogging (rust and ochreous deposits) are commonly known problems, particularly in hydraulic systems such as heating or cooling systems, wells and piping but also for water disinfection. These phenomena are potentially causing great damage to the system if they are not taken seriously or have negative impact on system performance. Scientists at the Leuphana University of Lüneburg developed a novel method to predict iron clogging in water and hydraulic systems.

Challenge

Ongoing corrosion processes most often remain invisible. When they are finally discovered due to system malfunction or losses in efficiency, often a costly and time-consuming revision of the damaged parts and the whole system is required.

A great help for an effective monitoring would be a predictive sensor technology, which would continuously measure critical parameters giving a clear read-out of the status of the system in terms of corrosion and iron clogging. This would prevent unexpected damage, e.g. total clogging of the system, and hence would be beneficial for the costs of maintenance (“predictive maintenance”). The use and dosing of anti-corrosion agents and other protective or maintenance measures thus could be optimized and monitored for security and performance.

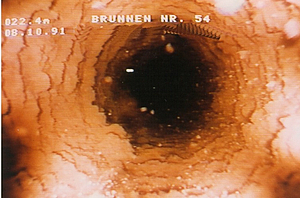

Picture of a well inspection showing clogging due to ochreous deposits. Source: Geothermie Neubrandenburg GmbH

Our Solution

Scientists at the Leuphana University of Lüneburg developed a novel method to monitor and predict iron clogging/rust build-up in water and hydraulic systems. This new sensor technology is based on electrochemical measurements of ferrous iron activities as well as other critical parameters and can be used to monitor corrosion processes and to estimate the potential of ferric hydroxide build-up.

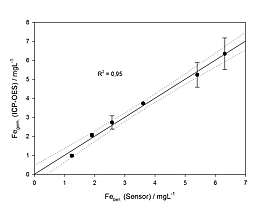

Statistical Analysis of calculated (Feber.) versus measured (Fegem.) ferric iron content showing very good correlation. The measurements were performed in two different irrigation wells. Source: Oliver Opel.

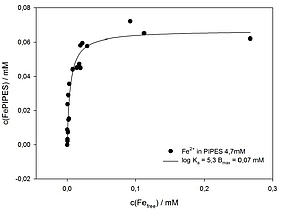

Monitoring Corrosion (iron clogging). The new and patented method was used to monitor free ferrous (electrochemical measurements of ferrous iron activities), caused by Fe-over-titration in PIPES, a Fe-complexing system (anti-corrosion agent). The method could be used to set-up a critical regulation point for a follow-up dosing of the exhausted anti-corrosion agent. Source: Oliver Opel.

Advantages

- Predictive and effective sensor technology for corrosion (electrochemical and microbial corrosion) and iron clogging (ochre and rust deposition) in the whole system.

- Robust measurement technology and high range sensitivity.

- Predictive maintenance due to simple and continuous measurement of critical water parameters.

- Better maintenance planning of the cleaning regime or use of anti-corrosion agents.

- Less costs: no need for a costly revision due to unforeseen failure.

Applications

- Can be used as a robust and mobile sensor system or easily integrated in existing monitoring systems (measurement of T, pH, Redox and DO).

- For all kinds of open or closed water systems.

Developmental Status

Proof of principle on real water systems.

Patent Status

An international PCT application has been nationalised and granted in Europe (EP2601511B1, validated in DE, FR, GB, AT, CH). Applicant: Leuphana Universität Lüneburg Stiftung Öffentlichen Rechts.

References

Opel et al.: Monitoring of microbially mediated corrosion and scaling processes using redox potential measurements. Bioelectrochemistry, 2014, 97:137-44.

Contact

Dr. Stefan Uhle

Patent Manager Life Science

Email: suhle(at)sciencebridge.de

Tel.: +49 551 30724 154

Reference: BioC-1271-ULü

Tags: Mess- und Analysetechnik